Mr Tony: +86-13913617685; Mr Scott: +86-13739160466

| Availability: | |

|---|---|

| Quantity: | |

PCCGN

MESURE

Product Application

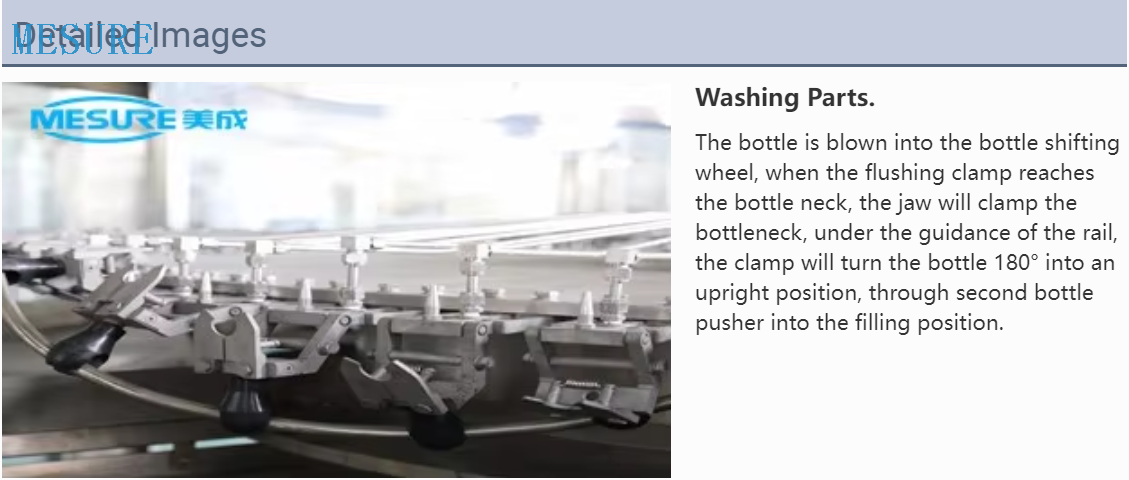

1. The sparkling beverage filing equipment adopts bottle neck holding transmission technology to realize fullyautomatic rinsing, filing and capping. This 3-in-1 sparkling beverage filing machine is mainly used for PET bottled gascontained drinks such as soda drinks.

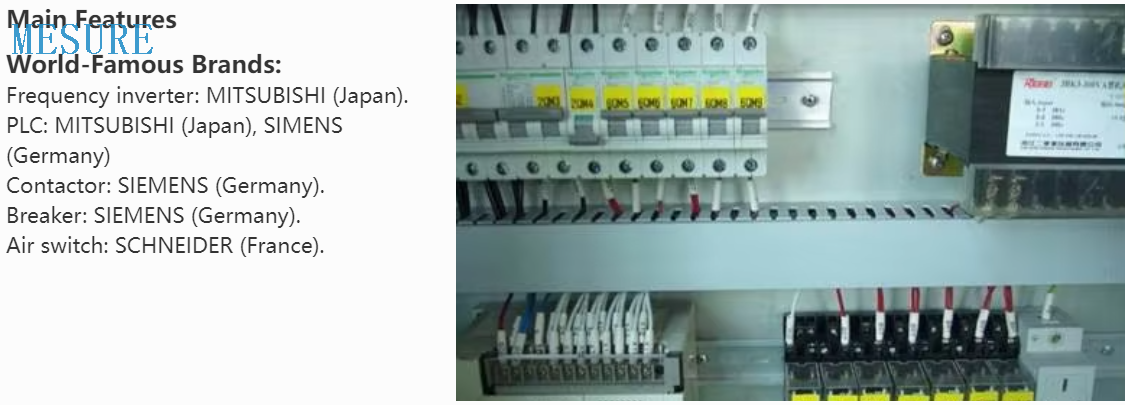

2. This carbonated-drinks filing machine adopts advanced PLC control technology. The main electric elements adoptMitsubishi, Omron, Siemens, etc international famous products. Each machine element that contacts with the liquid ismade of high-quality stainless steel.

Model | PCCGN18-00 | PCCGN24-00 | PCCGN32-00 | PCCGN40-00 | PCCGN50-00 | PCCGN60-00 |

Production Capacity (500ml) | 5000BPH | 8000-10000BPH | 10000-12000BPH | 12000-15000BPH | 15000-18000BPH | 18000-22000BPH |

Suitable Bottle Height | H=170-320,φ=50-100 | |||||

Spraying Pressure | 0.25-0.3 | |||||

Total Power | 2.3 | 3.0 | 5.5 | 7.5 | 9.0 | 15 |

Overall Dimension (L*W*H) | 2500*1760 *2650mm | 3100*2100 *2650mm | 3800*2800 *2650mm | 4000*3300 *3400mm | 4850*3650 *3300mm | 6500*5400 *3500mm |

Weight(KG) | 3500 | 4650 | 6800 | 8500 | 10000 | 12500 |

· Main Features

1. This series of filling machines are used in production of PET bottled carbonated beverage, such as carbonated watersprite and so on.

2. This series of products are the integrated rinsing, filing and capping machine, suitable for producing various PETbottled carbonated beverage.

3. The main machine adopts advanced PLC control technology.

4. The key electric elements adopt international famous products

5.We will give you the highest quality and the best service.

· Installation and Commissioning

After the equipments arrived buyer's workshop, the buyer should take it's place for each equipment according to thesupplied layout; the seller will send the experienced technician to guide the installation and debugging and trail productiorand fulfil the designed capability within the designed time

· Training

The seler will supply technical training to the buyer. The training is includes: equipment structure and maintenance,control and operation. After training, the technicians of the buyer will grasp relevant operation and maintenance skills. anccould adjust the technologies more skilled, and can deal with all kinds of malfunction in time

· After-sales Service

1. After qualified of the equipment, the seller will supply one year guarantee, control system one year guarantee, freecharge for wearing parts, and other spare parts with cost price. Within guarantee period, the technicians who acceptedtraining should strictly obey the requirements asked by the seller to operate the equipments and maintenance, to find thecommon malfunctions and fault clearing in time,; if the technicians of the buyer couldn't solve the problems themselves,the after-sales department will supply long range quide service by phone; if relevant measurements couldn't solve theproblems, the seller will send the technicians to the buyer factory, clear the fault or relevant technical problems on site, thecharges will reference to the installation and debugging charges.

2. After guaranteed, the seller will supply widely favorable technical support, after-sales service for the lifetime: favorableprice for the wearing parts and other spare parts.

Product Application

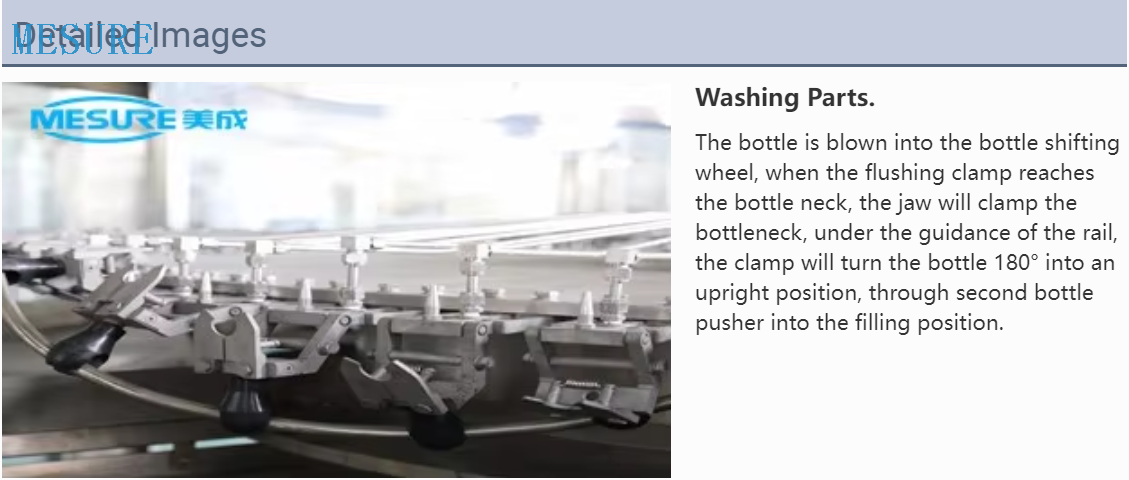

1. The sparkling beverage filing equipment adopts bottle neck holding transmission technology to realize fullyautomatic rinsing, filing and capping. This 3-in-1 sparkling beverage filing machine is mainly used for PET bottled gascontained drinks such as soda drinks.

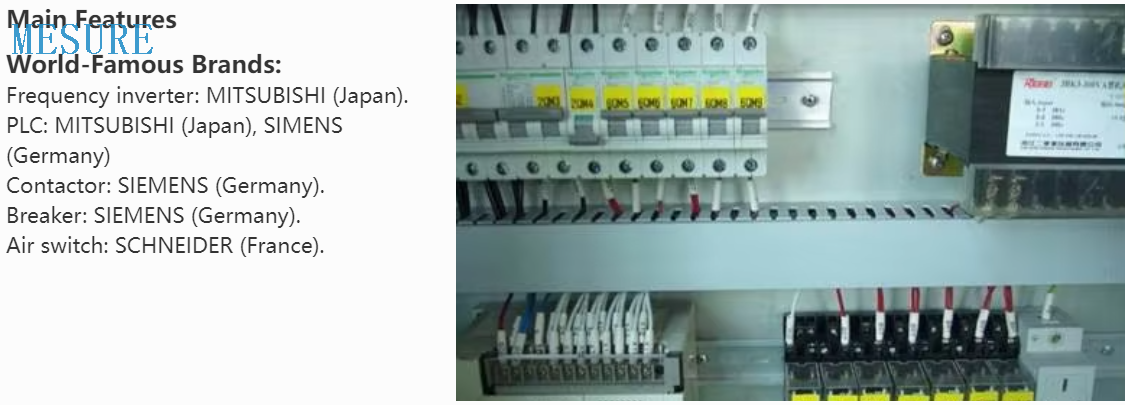

2. This carbonated-drinks filing machine adopts advanced PLC control technology. The main electric elements adoptMitsubishi, Omron, Siemens, etc international famous products. Each machine element that contacts with the liquid ismade of high-quality stainless steel.

Model | PCCGN18-00 | PCCGN24-00 | PCCGN32-00 | PCCGN40-00 | PCCGN50-00 | PCCGN60-00 |

Production Capacity (500ml) | 5000BPH | 8000-10000BPH | 10000-12000BPH | 12000-15000BPH | 15000-18000BPH | 18000-22000BPH |

Suitable Bottle Height | H=170-320,φ=50-100 | |||||

Spraying Pressure | 0.25-0.3 | |||||

Total Power | 2.3 | 3.0 | 5.5 | 7.5 | 9.0 | 15 |

Overall Dimension (L*W*H) | 2500*1760 *2650mm | 3100*2100 *2650mm | 3800*2800 *2650mm | 4000*3300 *3400mm | 4850*3650 *3300mm | 6500*5400 *3500mm |

Weight(KG) | 3500 | 4650 | 6800 | 8500 | 10000 | 12500 |

· Main Features

1. This series of filling machines are used in production of PET bottled carbonated beverage, such as carbonated watersprite and so on.

2. This series of products are the integrated rinsing, filing and capping machine, suitable for producing various PETbottled carbonated beverage.

3. The main machine adopts advanced PLC control technology.

4. The key electric elements adopt international famous products

5.We will give you the highest quality and the best service.

· Installation and Commissioning

After the equipments arrived buyer's workshop, the buyer should take it's place for each equipment according to thesupplied layout; the seller will send the experienced technician to guide the installation and debugging and trail productiorand fulfil the designed capability within the designed time

· Training

The seler will supply technical training to the buyer. The training is includes: equipment structure and maintenance,control and operation. After training, the technicians of the buyer will grasp relevant operation and maintenance skills. anccould adjust the technologies more skilled, and can deal with all kinds of malfunction in time

· After-sales Service

1. After qualified of the equipment, the seller will supply one year guarantee, control system one year guarantee, freecharge for wearing parts, and other spare parts with cost price. Within guarantee period, the technicians who acceptedtraining should strictly obey the requirements asked by the seller to operate the equipments and maintenance, to find thecommon malfunctions and fault clearing in time,; if the technicians of the buyer couldn't solve the problems themselves,the after-sales department will supply long range quide service by phone; if relevant measurements couldn't solve theproblems, the seller will send the technicians to the buyer factory, clear the fault or relevant technical problems on site, thecharges will reference to the installation and debugging charges.

2. After guaranteed, the seller will supply widely favorable technical support, after-sales service for the lifetime: favorableprice for the wearing parts and other spare parts.