Mr Tony: +86-13913617685; Mr Scott: +86-13739160466

Views: 0 Author: Site Editor Publish Time: 2025-04-14 Origin: Site

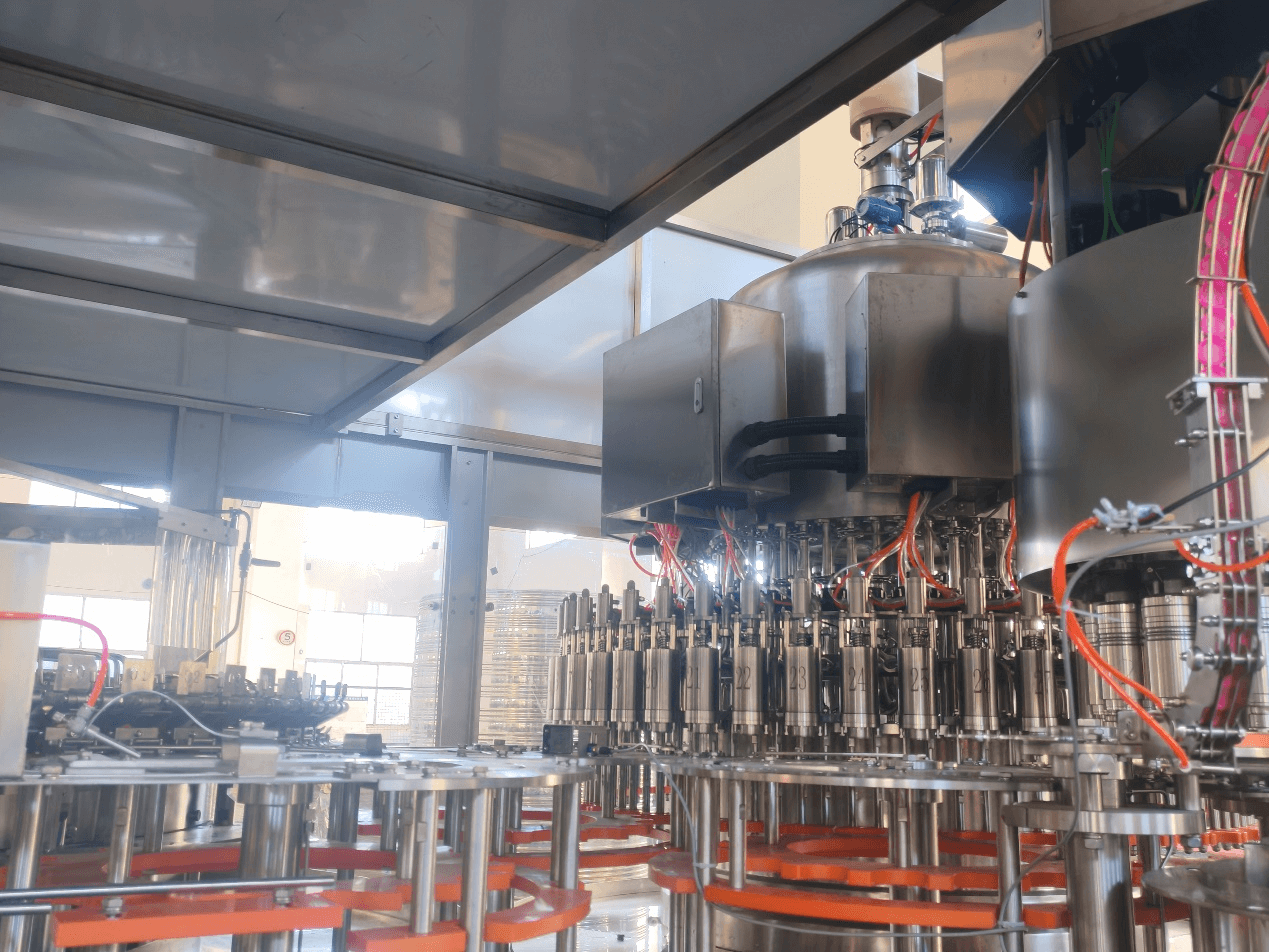

In 2024, Mesure customized a full servo flowmeter drinking water filling machine for customers with high quality requirements, and successfully delivered it to customers in February 2025. This machine is the second flowmeter filling machine purchased by the customer from Mesure. This machine is a flushing, filling and capping machine that integrates filling, capping and CIP cleaning systems. It is based on the introduction, digestion and absorption of foreign advanced technologies. According to the filling process requirements of water, emulsions, juices and other beverages in my country, it is independently developed and designed. It is a filling machine with domestic leading level. The machine adopts the bottleneck positioning and conveying method, and only a few changes are required to be applicable to bottles of various sizes. Through high-precision flowmeter filling, it meets the filling needs of high output, high precision and high quality, and meets the needs of rapid switching of production operations of multi-specification bottles (100ML-5L).

Project Specifications:

Applicable products: drinking water, carbonated beverages, juices, functional beverages, etc. (supporting a variety of liquid requirements)

Applicable bottle types: diameter range 50-105mm; bottle height range 150-320mm

Filling capacity: 30000BPH (500ML) / 18000BPH (1000ML) / 5000BPH (1.5L)

Working Process:

The bottle is driven by the bottle guide wheel after being sent in by the wind.

After the star wheel transmission transmits the bottle to the rinser, the rinser flips the guide rail to turn the bottle 180° up, and the bottle entering the filling machine is clamped by the bottle mouth stainless steel bottle clamp to hold the bottle mouth. After the detection switch senses the bottle signal, it sends a bottle signal to control the filling valve to open for filling. When the turbine flowmeter detects that the capacity reaches the set value, the pneumatic valve is closed to stop filling. After filling, the bottle is exported from the filling machine through the bottle star wheel and transmitted to the capping machine.

Flow Meter Filling Technology:

The 50-head flow meter filling uses variable frequency speed regulation technology, and the filling process is divided into two stages: high-speed filling in the initial stage to reduce waiting time, and slow and precise control in the later stage to avoid overflow. The high-precision turbine flowmeter is used, combined with the temperature and density automatic compensation function, to adjust the filling volume in real time to ensure the consistency of material volume and quality at different temperatures. The filling error is ≤±1.2ml, which is significantly better than the industry average of ±1%.

Equipped with servo motor and PLC to work together, greatly improving the machine's production capacity and stability. Customers can directly set parameters such as filling volume and speed, and monitor the operating status in real time, greatly reducing manual intervention in the production process. At the same time, multi-stage speed control and anti-drip vacuum back suction valve further reduce material loss and improve cleanliness.

It has strong environmental adaptability and durability, and is made of food-grade 304/316L stainless steel, which is corrosion-resistant and easy to clean, and meets the hygiene standards of the pharmaceutical and food industries. The flow meter is insensitive to interference such as vibration and temperature fluctuations, and is more suitable for complex workshop environments than weighing filling machines.

Customer Evaluation:

This model has been recognized and highly praised by customers. Since 2023, Mesure has conducted many technical exchanges with customers and finally decided to adopt the servo flowmeter filling system. After the first one was put into use, the excellent use status - continuous and stable high-precision filling, was highly praised by customers, and the second flowmeter filling machine was purchased in 2024.